Coating Thickness Measurement

X-RAY Fluorescence Measurement

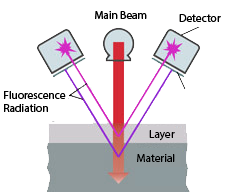

The measurement of the thickness of metal coatings on steel strip utilizes the X-ray fluorescence (XRF) effect. By selecting the operating parameters of the X-ray source, the filters of the detectors and the measurement geometry different applications can be realised.

The energy of the fluorescence radiation is characteristic for the element that produced the radiation. The radiation produced in the steel strip has a different energy as the fluorescence radiation produced in the coating e.g. Zinc. Using the method of differential filters one or the other component of the radiation can be selected for measurement. The detector modules installed in the gauge-head detect the selected radiation component in the backward directions, e.g. the radiation from the metal coating.

An increase in the coating thickness also increases the intensity of the fluorescence radiation of the coating. The measurement of the intensity of the fluorescence radiation allows a precise determination of the coating thickness. For coatings of binary alloys such as Zn/Al or Zn/Ni the detector modules measure the fluorescence radiation from both elements separately and it is thus possible to determine the total coating thickness and the coating composition.